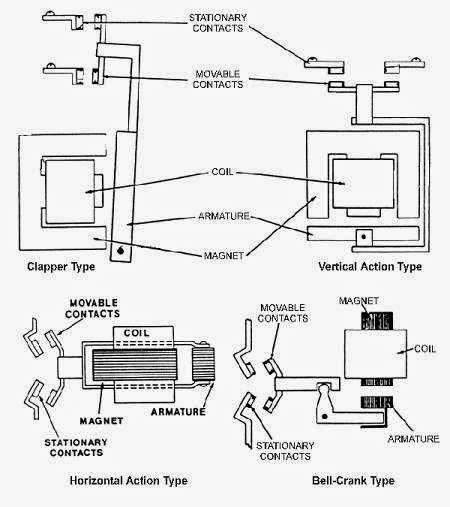

Figure 8.1 Magnetic Contactors

A contactor has three components. The contacts are the current carrying part of the contactor. This includes power contacts, auxiliary contacts, and contact springs. The electromagnet (or "coil") provides the driving force to close the contacts. The enclosure is a frame housing the contact and the electromagnet. Enclosures are made of insulating materials to protect and insulate the contacts and to provide some measure of protection against personnel touching the contacts. Open-frame contactors may have a further enclosure to protect against dust, oil, explosion hazards and weather.

The advantages of using magnetic contactors instead of manually operated control equipment include the following :

- Where large currents or high voltages have to be handled, it is difficult to build a suitable manual apparatus. Furthermore, such an apparatus is large and hard to operate. On other, it is a relatively simple matter to build a magnetic contactor that will handle large current or high voltages and the manual apparatus must control only the coil of the contactor

- Contactors allow multiple operations to be performed from one operator (one location) and interlocked to prevent false and dangerous operations

- Where the operation must be repeated many times an hour, a distinct saving i effort will result if contactors are used. The operator simply has to push a button and the contactors will automatically initiate the proper sequence of events

Types of magnetic Contactors :

There are four basic types of electromagnetic contactors :

Figure 8.2 Magnetic contactors type

- Clapper Type - It contains a hinged armature that pivots to seal in, thus closing the moveable contacts against the stationary contacts.

- Horizontal Action - The armature and the contacts move horizontally in a straight line.

- Vertical Action - The armature and contacts move in a straight vertical line.

- Bell Crank - A bell crank converts the vertical movement of the armature into a horizontal motion. Longer contact life and reduced contact bounce result from lessened shock on armature pickup.

Source :

http://en.wikipedia.org/wiki/Contactor

http://ecmweb.com/content/basics-contactors

http://www.myodesie.com/index.php/wiki/index/returnEntry/id/2976

Petruzella, Frank. (1995). Industrial Electronics. Mc Graw Hill.216-218